A pneumatic valve is a component used to control the flow of air in a pneumatic system. In such systems, compressed air is used to control machines, cylinders, or tools. The valve determines exactly where, when, and how much air flows through the system. The function of a valve is to control and direct the compressed air. Depending on the application, a pneumatic valve can allow air to pass through, shut it off, change its direction, or regulate the pressure and speed of the air flow. This allows pneumatic valves to be used as control valves, regulating valves, or even safety valves. In dangerous situations, they can automatically shut off the air supply or depressurize the system completely to prevent damage or injury.

Each valve essentially consists of three main components:

1. Connections (ports) Valves usually have 2, 3, or 5 ports.

- With two ports, one is for the air supply and one is for the work (e.g., a cylinder).

- A third port is often used for venting.

- Five ports are found on valves that control double-acting cylinders: one port for supply, two for work and two for venting. A port is simply a threaded opening into which a coupling is inserted. Usually a push-in coupling for direct hose connection.

2. Housing with switching mechanism The housing contains the mechanism that directs the compressed air to the correct port. Depending on the type of valve and the application, different switching techniques can be used, such as slide valves, poppet valves, or diaphragm valves.

3. control The control ensures that the valve switches at the right moment. This can be done in various ways:

- Manually (e.g., push button)

- Mechanically (e.g., by touch or movement)

- Pneumatically (by air pressure)

- Electrically (via solenoid coils)

How does a valve work?

Pneumatic valves are distinguished based on the number of connections (ports) and the number of switching positions. In addition, the type of control plays a role: valves can be monostable or bistable, and function as NO (normally open) or NC (normally closed). The various valves can be used to perform different functions in a pneumatic system.

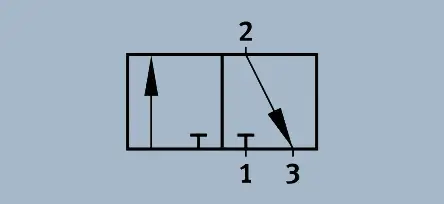

3/2 Valve

A 3/2 valve has three ports: one for the supply (1), one for the working (2), and one for the exhaust (3). The valve has two switching positions. Because there is only one working outlet, this valve can only fill one chamber with compressed air. This makes the valve suitable for single-acting cylinders, where the return stroke is achieved mechanically, for example with a spring.

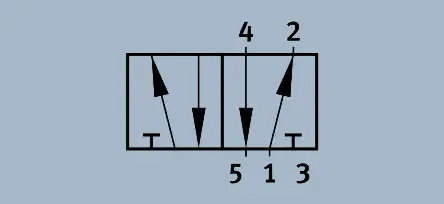

5/2 Valve

Like the 3/2 valve, a 5/2 valve has two switching positions, but has five ports: one for supply, two for work (4), and two for venting (5). This allows both chambers of an actuator to be vented and deaerated, providing complete control over both sides of the cylinder. With a 5/2 valve, it is therefore possible to achieve a movement that is completely pneumatic.

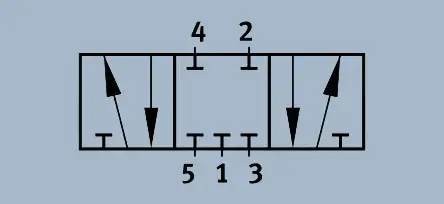

5/3 Valve

A 5/3 valve has the same number of ports as the 5/2 variant, but has an additional switching position: the middle position. This position offers an uncontrolled position and is often used in safety-critical systems.

There are three types of center position:

- Closed center position: all ports are closed. No air can enter or escape, allowing the cylinder to maintain its position. However, small internal leaks can cause the cylinder to lose pressure over time.

- Ventilated center position: both working ports are connected to the supply. The cylinder is ventilated on both sides, keeping it balanced. In cylinders with unequal piston surfaces, this can lead to slight movement.

- Ventilated center position: the supply is closed and both working ports are open to the atmosphere. The cylinder is depressurized on both sides and can therefore move easily when a slight external force is applied.

What is the difference between a 3/2 and a 5/2 valve?

A 3/2 valve is used with single-acting cylinders, where only one chamber is filled with

compressed air and the return stroke is mechanical. A 5/2 valve is used with double-acting cylinders, where both chambers are supplied with air for full forward and return movement. A 5/3 valve has an additional middle position and is used when a cylinder must remain in position, be balanced, or be depressurized, for example in safety-critical or positioning

systems.

Normally Closed (NC) and Normally Open (NO)

- The terms Normally Closed (NC) and Normally Open (NO) indicate the position of the valve when it is not energized.

- In an NC valve, the air supply is shut off, so no air flows through it. With an NO valve, the air supply is open; the working port is supplied with air when at rest.

Note the difference with electrical systems: in electricity, NC means that the circuit is closed and therefore current is flowing. In pneumatics, you think in terms of ports. Open or closed for pneumatic applications, whereas in electricity you think in terms of bridges. Open or closed for current.

Mono- and bi-stable valves

In addition to the control method, the number of controls also plays a role in the operation of a valve. There are monostable (single) and bistable (double) versions.

Monostable valve

A monostable valve has a single control. When energized, the valve switches, and as soon as the control is released, it automatically returns to its rest position, usually by means of a spring or air pressure.

Bistable valve

A bistable valve has two controls. It switches with a short pulse and remains in that position until the second control is activated. This allows the valve to remain stable in both positions, which is useful in applications where the position must be maintained in the event of a power failure or emergency stop.

WHAT TYPES OF PNEUMATIC VALVES ARE THERE?

There are various types of pneumatic valves, each with a specific function within an air-controlled system. These include pressure control valves, check valves, throttle valves, solenoid valves, and changeover valves. A throttle valve regulates the speed of a cylinder by limiting or controlling the air flow, allowing pneumatic actuators to perform movements with greater precision. A solenoid valve is electrically controlled by an electromagnet and can quickly open or close a valve, enabling automation and precise timing of the air supply. A changeover valve directs compressed air from one outlet to another, depending on the switch position, and is often used to operate double-acting cylinders in two directions, for example. By combining these different valves, pneumatic systems can be controlled efficiently, reliably, and safely.